Hoshizaki PT1A-FG-FG Manual

Læs gratis den danske manual til Hoshizaki PT1A-FG-FG (48 sider) i kategorien Køleskab. Denne vejledning er vurderet som hjælpsom af 15 personer og har en gennemsnitlig bedømmelse på 4.3 stjerner ud af 8 anmeldelser.

Har du et spørgsmål om Hoshizaki PT1A-FG-FG, eller vil du spørge andre brugere om produktet?

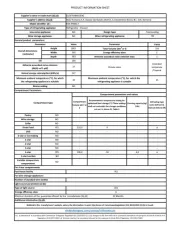

Produkt Specifikationer

| Mærke: | Hoshizaki |

| Kategori: | Køleskab |

| Model: | PT1A-FG-FG |

Har du brug for hjælp?

Hvis du har brug for hjælp til Hoshizaki PT1A-FG-FG stil et spørgsmål nedenfor, og andre brugere vil svare dig

Køleskab Hoshizaki Manualer

Køleskab Manualer

- Traulsen

- Vedette

- Bertazzoni

- Koenic

- G3 Ferrari

- Fisher & Paykel

- Gourmia

- Scancool

- Follett

- Sunny

- Vestfrost

- Lec

- Finlux

- IFB

- Silverline

Nyeste Køleskab Manualer