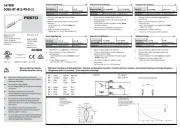

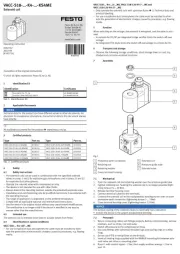

Festo CPX-E-PB Manual

Læs gratis den danske manual til Festo CPX-E-PB (4 sider) i kategorien Ikke kategoriseret. Denne vejledning er vurderet som hjælpsom af 6 personer og har en gennemsnitlig bedømmelse på 5.0 stjerner ud af 3.5 anmeldelser.

Har du et spørgsmål om Festo CPX-E-PB, eller vil du spørge andre brugere om produktet?

Produkt Specifikationer

| Mærke: | Festo |

| Kategori: | Ikke kategoriseret |

| Model: | CPX-E-PB |

Har du brug for hjælp?

Hvis du har brug for hjælp til Festo CPX-E-PB stil et spørgsmål nedenfor, og andre brugere vil svare dig

Ikke kategoriseret Festo Manualer

Ikke kategoriseret Manualer

- Microsoft

- Rocket Espresso

- LaCie

- Roline

- MilanToast

- Metra

- Huslog

- Whale

- PowerColor

- EA Elektro Automatik

- Legrand

- Jetson

- Baby Annabell

- LEA

- Ave Six

Nyeste Ikke kategoriseret Manualer