Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

LOCTITE® is a registered trademark of its respective trademark holder in certain

countries.

1 Applicable documents

Documents Product Contents

Instructions Angle seat valve VZXA Operating

Addendum document Angle seat valve VZXA Operating conditions

Safety data sheet Adhesive from the original manu

facturer

e.g. LOCTITE270

Tab. 1

2 Safety

2.1 Safety instructions

– Before carrying out any work on the product, switch off the compressed air

supply and secure it against being switched back on.

– Observe the safety data sheet for the adhesive from the original manufac

turer.

– The magnet is fragile and strongly magnetic.1

– Handle the magnet carefully.

– Store the magnet at least 20cm away from magnetisable objects.

2.2 Intended use

Installation of a position indicator on an angle seat valve VZXA.

3 Product Range Overview

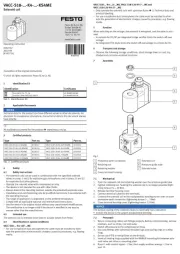

3.1 Scope of delivery

1Magnet (1x)

2Rod (1x)

3Sensor bracket (1x)

Fig. 1

3.2 Not in scope of delivery

4Angle seat valve (1x)

VZXA

5Locking agent (1x)

e.g.LOCTITE270

Fig. 2

4 Assembly

A distinction is made between the following control functions of the angle seat

valve :4

– Double acting (D/A)

– Normally closed (N/C)

– Normally open (N/O)

4.1 Preparation

4.1.1 For angle seat valves with D/A and N/C control function

Fig. 3

1. Clamp the angle seat valve in a vice on the edges[X] of the spine.4

2. Remove the sight cap[A].

3. If the connector[B] was unscrewed together with the inspection cap[A],

detach it from the inspection cap[A].

– Do not damage the thread of the connector[B].

– Screw the connector[B] back into the angle seat valve .4

4. Use an auxiliary tool to engage into the slots[Y].

Auxiliary tool: 5mm thick, 35mm wide

5. Tighten connector[B]. Tightening torque: 20Nm±10%

Fig. 4

1. Pressurise the angle seat valve with compressed air at port 2.4

ÄThe piston rod[E] travels to the top end position.

2. Pull off display part[C].

3. Unscrew the retaining bracket[D] from the piston rod[E]. Hexagon: 5mm

4. If necessary, remove objects from the angle seat valve . Clean coarse con4

tamination. Objects: e.g.thread abrasion

8128632

SAMH-F12-MK

Position indicator

8128632

202008

[8128634]

Assembly instructions

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 3470

www.festo.com