Little Giant HT-6E-CIA-FS Manual

Little Giant

Vandpumpe

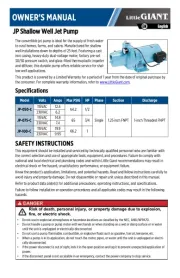

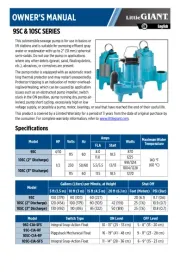

HT-6E-CIA-FS

| Mærke: | Little Giant |

| Kategori: | Vandpumpe |

| Model: | HT-6E-CIA-FS |

Har du brug for hjælp?

Hvis du har brug for hjælp til Little Giant HT-6E-CIA-FS stil et spørgsmål nedenfor, og andre brugere vil svare dig

Vandpumpe Little Giant Manualer

11 December 2025

10 December 2025

10 December 2025

9 December 2025

24 August 2025

24 August 2025

24 August 2025

23 August 2025

22 August 2025

21 Juni 2025

Vandpumpe Manualer

- Alphacool

- Vetus

- Makita

- Zipper

- Dedra

- Lavor

- CMI

- Bavaria

- Dimplex

- WilTec

- Duro Pro

- Cocraft

- Gardena

- Anova

- SereneLife

Nyeste Vandpumpe Manualer

1 December 2025

1 December 2025

1 December 2025

1 December 2025

30 November 2025

30 November 2025

30 November 2025

29 November 2025

27 November 2025

25 November 2025