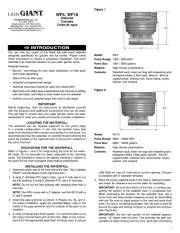

Little Giant TP 553674 Manual

Little Giant

Pumpe

TP 553674

| Mærke: | Little Giant |

| Kategori: | Pumpe |

| Model: | TP 553674 |

Har du brug for hjælp?

Hvis du har brug for hjælp til Little Giant TP 553674 stil et spørgsmål nedenfor, og andre brugere vil svare dig

Pumpe Little Giant Manualer

31 December 2026

29 December 2026

19 December 2025

15 December 2025

15 December 2025

9 December 2025

9 December 2025

22 August 2025

6 Juli 2025

6 Juli 2025

Pumpe Manualer

- Kärcher

- Pontec

- Zipper

- Outwell

- Topeak

- Hayward

- Generac

- Eheim

- Gardena

- Osram

- SilverCrest

- Liberty Pumps

- Hozelock

- Flo

- Blackburn

Nyeste Pumpe Manualer

5 Januar 2026

1 Januar 2026

31 December 2026

31 December 2026

31 December 2026

30 December 2026

30 December 2026

30 December 2026

30 December 2026

30 December 2026