Zurn Z1186-ST Manual

Zurn

Ikke kategoriseret

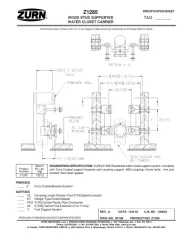

Z1186-ST

| Mærke: | Zurn |

| Kategori: | Ikke kategoriseret |

| Model: | Z1186-ST |

Har du brug for hjælp?

Hvis du har brug for hjælp til Zurn Z1186-ST stil et spørgsmål nedenfor, og andre brugere vil svare dig

Ikke kategoriseret Zurn Manualer

10 December 2025

9 December 2025

9 December 2025

3 December 2025

3 December 2025

3 December 2025

3 December 2025

3 December 2025

3 December 2025

12 November 2025

Ikke kategoriseret Manualer

- Airlive

- HTW

- Eonon

- Ednet

- First Alert

- Louis Tellier

- Primera

- Tech 21

- Cudy

- Vestil

- Code Mercenaries

- Cleco

- Gaslock

- Elation

- Milectric

Nyeste Ikke kategoriseret Manualer

10 December 2025

10 December 2025

10 December 2025

10 December 2025

10 December 2025

10 December 2025

10 December 2025

10 December 2025

10 December 2025

10 December 2025