Hypercardioid Dynamic Instrument Microphone

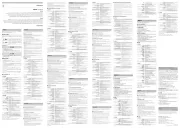

SCALE IS 5 DECIBELS PER DIVISION

Polar pattern Hypercardioid

Frequency response 30-12,000 Hz

Open circuit sensitivity -54 dB

Dimensions 82.5 mm - long,

38.0 mm - maximum diameter

Output connector Integral 3-pin XLRM-type

Accessories furnished AT8665 drum mount for 5/8"-27 threaded

5/8"-27 to 3/8"-16 threaded adapter;

•Tailoredtocapturesoundfromrackandfloortoms,snaredrumsand

otherpercussioninstruments

•HandlesveryhighSPLatcloserange

•Hypercardioidpolarpatternreducespickupofsoundsfromthesides

andrear,improvingisolationofdesiredsoundsource

•Rareearthmagnetforimprovedoutputandtransientresponse

•Low-profiledesignpermitsversatileplacementarounddrumkit

•Rugged,all-metalconstructionensuresdependableperformancein

live-musicandstudioapplications

•Integral5/8"-27threadedstandclampworkswithincludeddrum

mounttopermitmountingofmictodrumrim

The ATM230 is a dynamic microphone with a hypercardioid polar pattern. It

is designed specically for musical instrument pickup in the studio and on

The hypercardioid polar pattern of the microphone is more sensitive to

sound originating directly in front of the element, making it useful for

controlling feedback and reducing pickup of unwanted sounds.

The output of the microphone is a 3-pin XLRM-type connector.

The microphone is enclosed in a rugged housing and is outtted with an

integral 5/8"-27 threaded stand clamp. The included AT8665 drum mount

screws into the stand clamp to permit mounting of the ATM230 to the rim

of a drum. A soft protective pouch is also included.

Output is low impedance (Lo-Z) balanced. The signal appears across Pins 2

and 3; Pin 1 is ground (shield). Output phase is “Pin 2 hot”- positive acoustic

pressure produces positive voltage at Pin 2.

To avoid phase cancellation and poor sound, all mic cables must be wired

consistently: Pin 1-to-Pin 1, etc.

Avoid leaving the microphone in the open sun or in areas where

temperatures exceed 43° C for extended periods. Extremely high humidity

Take care to keep foreign particles from entering the windscreen. An

accumulation of iron or steel filings on the diaphragm, and/or foreign

material in the windscreen's mesh surface, can degrade performance.