The safety factor is the ratio of the

ultimate break strength

ultimate break strength

ultimate break strength

ultimate break strengthultimate break strength

working load limit

working load limit

working load limit

working load limitworking load limit

. The ultimate break strength rep-

resents the force at which a part will structurally fail. The

working load limit is the maximum load that the user shall ap-

ply. The safety factor provides a margin of safety above the

working-load limit to accommodate normal dynamic loading

The use of mounting configurations other than recommended

by Electro-Voice in this manual are at the risk of the user.

Suspending any object is potentially dangerous and

should only be attempted by individuals who have a

thorough knowledge of the techniques and regula-

tions of suspending objects overhead. Electro-Voice

strongly recommends that loudspeakers be suspen-

ded taking into account all current national, federal,

state, and local laws and regulations. It is the re-

sponsibility of the installer to ensure all loudspeak-

ers are safely installed in accordance with all such

requirements. When loudspeakers are suspended,

Electro-Voice strongly recommends the system be in-

spected at least once per year or as laws and regula-

tions require. If any sign of weakness or damage is

detected, remedial action should be taken immedi-

ately. The user is responsible for making sure the

wall, ceiling, or structure is capable of supporting all

objects suspended overhead. Any hardware used to

suspend a loudspeaker not associated with Electro-

Voice is the responsibility of others.

Prior to use, inspect the suspension points and associated

hardware for any cracks, deformations, broken welds, corro-

sion, missing or damaged components which could reduce the

suspension points strength. Replace any damaged hardware.

Never exceed the limitations or maximum recommended load

intended for the suspension points. As an added safety meas-

ure, it is suggested the user install an extra suspension point

back to the building structural supports. This redundant safety

point should have as little slack as possible (less than one inch

is preferable). Prior to each use, inspect the loudspeaker en-

closures for any cracks, deformations, missing or damaged

components, which could reduce enclosure strength. Replace

any loudspeaker systems that are damaged or missing hard-

For information on warranty periods and after sales service,

please visit: www.electrovoice.com/warranty

Make sure that all parts are included and not damaged. If the

packaging or any parts are damaged, contact your shipper. If

any parts are missing, contact your Sales or Customer Service

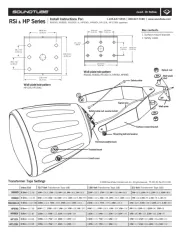

1 Bracket with through hole

1 Bracket with slotted hole

2 Screw, M6x20, Phillips, Pan Head, Steel,

1 Quick installation guide

Thank you for choosing ZLX-G2-BRKT accessory. This manual

describes how to install the mounting bracket with the ZLX-G2

full-range loudspeaker system.

The ZLX-G2-BRKT is used to mount a ZLX-12-G2, ZLX-12P-G2,

ZLX-15-G2, or ZLX-15P-G2 full-range loudspeaker to a wall,

ceiling, pole, pipe, or truss.

The mounting bracket kit contains the following:

1 Bracket with through hole

1 Bracket with slotted hole

2 Screw, M6x20, Phillips, Pan Head, Steel,

1 Quick installation guide

Fig.1: 12-inch and 15-inch powered version

Mounting the U-bracket to the wall or ceiling

Due to the weight of the Electro-Voice loudspeaker

system, it is imperative the bracket is properly se-

cured to the wall. The choice of fastener (not sup-

plied) will be determined by the material and con-

struction of the mounting surface. The user is re-

sponsible to ensure the mounting surface and fasten-

ers are capable of supporting the weight of the loud-

We recommend that two or more persons lift and

place heavier loudspeakers. Single person lift and

placement of heavier loudspeakers could cause in-

For vertical or horizontal mounting using four screws OR

pole/truss mounting for nominal pipe size up to 2" (DN50)

using two U-bolts. Accepts fastener diameters up to 3/8" or

M10. Refer to for slot dimensions.Technical data

For horizontal suspension using two threaded rods up to

5/8" or M16 diameter OR pole/truss mounting using two

Electro-Voice TCA-1 truss clamp adapters.

For pole mounting using one U-bolt for nominal pipe size

between 4" (DN100) and 6" (DN175). Accepts fastener dia-

meters up to 5/8" or M16. Refer to for slotTechnical data

For horizontal suspension using two threaded rods OR ver-

tical or horizontal mounting using two screws. Accepts

fastener diameters up to 3/8" or M10.

Fig.2: Vertical or horizontal wall mounting using four 3/8” or M10

Fig.3: Vertical pole mounting using 2” or DN50 U-Bolts

Fig.4: Horizontal pole/truss mounting using 2” or DN50 long U-Bolts

Fig.5: Horizontal suspension using 1/2” or M16 threaded rods

Fig.6: Horizontal mounting using TCA-1 truss clamps

Fig.7: Vertical mounting using TCA-1 truss clamps

Fig.8: Horizontal pole/truss mounting using 4” to 6” or DN100 to

Fig.9: Vertical or horizontal wall mounting using two 3/8” or M10

Fig.10: Horizontal suspension using 3/8” or M10 threaded rods

Attaching the bracket to the loudspeaker

1. Using a screwdriver with a hex drive, remove the four

screws that hold the top and bottom handles to the en-

Keep the eight handle mounting screws. These

screws are necessary to install the smaller brackets.

When mounting the loudspeaker in a vertical orienta-

tion, the bracket with slotted hole needs to be in-

stalled at the bottom of the loudspeaker.

2. Using the eight screws removed from the handles, install

the two smaller brackets to the top and bottom of the