In accordance with AS/NZS 6400

side o f th e op era tor.

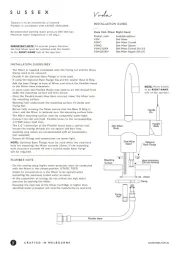

- The Mixer is supplied assembled, only the Fixing nut and the Brass Clamp need to be removed.

- Decide if the Optional Base Flange is to be used.

- If using the Optional Base Flange discard the smaller Base O Ring.

- Add the base Flange to base of Mixer and attach the Flexible Hoses to the Mixer Hose extensions.

- In some cases the Flexible Hoses may need to be fed through from under the mounting surface and then attach.

- Once the Flexible Hoses have been secured, lower the Mixer onto the mounting surface.

- Working from underneath the mounting surface fit Clamp and Fixing Nut.

- Before fully securing the Mixer ensure that the Base O Ring is intact and the Mixer is centered over the mounting

- The Mixer mounting surface must be completely water-tight.

- Connect the Hot and Cold Flexible hoses to the corresponding 1/2”BSP water feed lines.

- The 1/2” connection of the Flexible hoses have a conical seal, ensure the mating threads are cut square and burr

- Isolating stop valves are recommended with all installations. (not supplied)

- Ensure all fittings and connections are water-tight.

Note: Optional Base Flange must be used when the clearance hole for mounting the Mixer exceeds 35mm. If the

mounting hole clearance exceeds 45 mm a custom made Base flange will be required.

- On-site testing using higher water pressures must be conducted with the Mixer in the closed position.

- Under no circumstances is the Mixer to be opened when exceeding the maximum stated water pressure.

- At the completion of testing, do not relieve any high water pressure by operating the Mixer.

- Exposing the internals of the Mixer Car tridge to higher than specified water pressures will void the

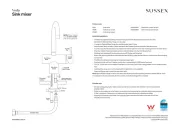

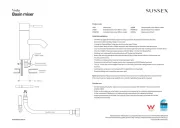

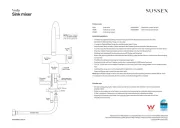

VSMCSSRH Sink mixer curved 316 S/S

VSMQSSRH Sink mixer square 316 S/S

Tapware is to be installed by a Licensed Plumber in accordance with AS/NZS 3500:2003

Recommended working water pressure 300-500 kpa. Maximum water temperature is 65 deg.c