1

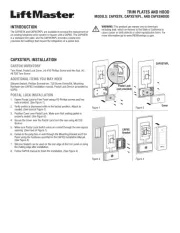

NOTE: The following images are for reference only. Your unit and shaft collar may

look different.

You may need:

• 3/8" (10 mm) Open End Wrench

• 3/16" (5 mm) Hex Key Wrench

Shaft Collar

Model 041D8615

Included Items

Shaft Collar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (1)

WARNING: This product can expose you to chemicals including

lead, which are known to the State of California to cause cancer or

birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov

To prevent possible SERIOUS INJURY or DEATH:

• Disconnect ALL electric and battery power BEFORE performing ANY service or

maintenance.

To prevent damage to the receiver logic board, DO NOT touch printed circuit

board of replacement receiver logic board during installation.

ALWAYS wear protective gloves and eye protection when changing the battery or

working around the battery compartment.

1. Close the

garage door.

2. Disconnect

power from

the outlet and

remove the battery

if applicable.

3. To remove the battery,

press the clip to remove

the connector from the

unit (A).

4. Remove wires from the

unit and label them for

reinstallation. Disconnect

wires from the quick

connect terminals (B).

5. Loosen the shaft collar.

Use a 3/16" (5mm) hex

key wrench to loosen the

shaft collar (C).

7. Using a 3/8" (10 mm) open

end wrench, remove the two

14-10 x 2" screws holding

the mounting bracket to the

wall .(E)

8. Remove the motor unit

from wall.

9. Discard the old shaft collar.

Battery

Backup Cord

475LM

Battery Backup

Connector

WHT/

BLK

WHT

A

B

Collar Screws

Shaft Collar

3/16" (5 mm)

Hex Key Wrench

Collar Screws Set Screws

C

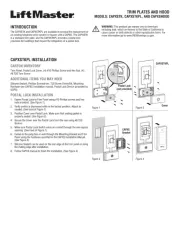

1. Close the garage door.

2. Disconnect power from

the outlet and remove the

battery if applicable.

3. Open the front panel (A).

4. Remove the battery cover.

Disconnect the battery (if

applicable). Remove the

battery and set aside (B).

5. Remove wires from the

unit and label them for

reinstallation.

Disconnect wires

from the quick

connect terminals (C).

6. Loosen the shaft collar.

Use a 3/8" (10 mm) open

end wrench to loosen the

shaft collar (D).

7. Using a 3/8" (10 mm) open end wrench,

remove the two 14-10 x 2" screws holding

the mounting bracket to the wall (E).

8. Remove the motor unit from wall.

9. Discard the old shaft collar.

Set Screws

Motor Shaft

Shaft Collar

Mounting Bracket

Screws

14-10 x 2"

E

A

B

C

D

Follow these steps for shaft collars

that install with a hex key wrench

Follow these steps for shaft collars

that install with an open end wrench