Part No. CT-1700

OPERATION INSTRUCTIONS

Contour Crimp

CONTROLLED CYCLE

CRIMPING TOOL

Crimps Panduit #8 - #1 AWG

copper lugs and splices, #6 - #4

AWG aluminum lugs and splices,

#8 - #2 AWG non-insulated S series

tubular terminals; and #16 AWG -

#3 AWG copper CTAPF taps.

Provides UL Listed and CSA Certified terminations

with applicable Panduit terminals.

COPPER AND ALUMINUM COMPRESSION

CONNECTOR CRIMPING INSTRUCTIONS

OPERATION INSTRUCTIONS

PA23614A01

Rev.: 05 3-2017

CT-1700

Figure 1

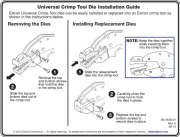

1. With the handles in the position,open

depress die release and rotate die to desired

pocket. The pocket will lock in place when an

audible “click” is heard (Die index number and

color appear to the left of corresponding

pocket).

CAUTION: Do not cycle tool unless the die

release button has seated and the die has

locked in place.

Refer to product packaging for selection of the

proper crimp pocket. Place the desired

compression connector in the crimp pocket

(See Fig. 2).

2. Close handles until the connector is held

snugly in position—do not deform the barrel.

3. Remove end plug(s) [for aluminum

compression connectors only]. Insert the

stripped wire into the connector until the wire

stops. Refer to product packaging for wire

strip length.

4. Crimp the connector by closing the handles

until the controlled cycle mechanism releases.

Repeat this operation for the compression

connectors that require more than one

compression.

Upon release, the handles will open

automatically and the crimped connector can

be removed.

After crimping, inspect that the crimp is

centered on the barrel in order to achieve

optimal pullout performance. Also, inspect die

index number embossed in connector by crimp

die.

© Panduit Corp. 2017

Email:

techsupport@panduit.com

EU Website: www.panduit.com/emea

EU Email: emeatoolservicecenter@panduit.com

Technical Support

Tel: 1-800-777-3300

Panduit Europe • EMEA Service Center

Tel: +31 546 580 452 • Fax: +31 546 580 441

CAUTION: Verify power is “OFF” before

working on wiring with this tool. The

cushioned grips are for the user’s

comfort, and are not intended to insulate

against shock while working on live

electrical circuits.

Page: 1 of 2

Rotating Crimp

Die Wheel

Crimp Die Release Push Button

Figure 2

DIE INDEX NUMBER

EMBOSSED FOR

INSPECTION

www.panduit.com

CRIMP POCKETS FOR

Panduit Compression

Connectors. Refer to product

packaging for wire range and

proper crimp pocket. Crimp

pockets are identified with

applicable die index number

and color code.

Controlled cycle mechanism

prevents tool f rom opening

before crimp cycle is

complete.

Manual release lever, push

forward in the event that

controlled cycle mechanism

must be released.

Cushioned Handle Grips